Die castings are monolithic. PHB can provide components and assemblies in prototyping and low-volume production quantities using a multitude of methods, including (but not limited to): Aluminum die casting alloys are lightweight and possess high dimensional stability for complex part geometries and thin walls. document.getElementById( "ak_js_10" ).setAttribute( "value", ( new Date() ).getTime() ); document.getElementById( "ak_js_11" ).setAttribute( "value", ( new Date() ).getTime() ); For the past many years, Roche Industry provides on-demand manufacturing services using processes like 3D printing, CNC machining, vacuum casting, injection molding, and much more. With the added expense of creating separate tooling for all of the castings, and the additional time and expense involved in aiming these eight castings, our customer realized it was time for a new solution. Our flexible in-house capabilities include: Whether you need help with new tooling or need us to take in your transferred tooling, our onsite 12,000 square foot tooling facility and our skilled Die Cast Engineers are ready to meet your needs. Fin dall'anno 2000 ci siamo occupati di consulenza informatica, giuridica e commerciale. Were excited to start working with you! After 50 plus years we now occupy a 35,000 sq. We secured the equipment and business from a prominent Canadian Brass Die Caster. In 1999 after 40 years in Berkley, the company moved into a brand new state-of-the-art facility in Hercules, California. Aluminum Die Casting Company was started in 1950 by Mr. Gene Woods and Mr. Larry Strom. MES delivers best-in-class, ISO:9001 certified die casting. Die cast solutions for every industry. Not sure what alloy you need? Our 58 presses range in size from 250 ton to 2000 ton producing aluminum die casting components for low and high volume production programs. Each of our machines is paired with an individual furnace providing us ultimate flexibility. Our goal is to efficiently improve the functionality and manufacturability of your designs. Because die castings do not consist of separate parts that have been welded or fastened together, the strength of the material determines the strength of the part, rather than a strength that depends on threads or welds. Anche noi da una piccola idea siamo partiti e stiamo crescendo. Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. Read more on MAGMAsoft and the aluminum die casting process. Twenty-one years later, Ben proudly opened the doors of Benda Tool in Berkeley, California. Discover rigorous, industry-leading quality standards. Depending on the type of metal being cast, a hot-or cold-chamber machine will be used. We can provide packaging layered or by cell. One more step to ensure our customers are receiving the highest quality product. With the addition to our new, digital high speed equipment, and our team of skilled craftsmen we have the capacity to service your needs into the 21st century and beyond. J&M Precision Die Casting achieves ISO9001:2015 certification! ft. facility.

Experience the Carteret advantage and let our capable sales and service staff assist you from the quote process through production. From metal castings to gravity die castings, we specialize in die castings for the automotive, lighting, and construction industries. Our 100,000 square foot facility is conveniently located in the heart of the Midwest, just 30 miles North of Dayton, Ohio off I-75. Address: 6918 Beck Ave, North Hollywood, CA 91605, United States. J&M Precision Die Casting adds SpectroMaxx. It is mandatory to procure user consent prior to running these cookies on your website. !function(d,s,id){var js,fjs=d.getElementsByTagName(s)[0];if(!d.getElementById(id)){js=d.createElement(s);js.id=id;js.src="//platform.twitter.com/widgets.js";fjs.parentNode.insertBefore(js,fjs);}}(document,"script","twitter-wjs"); Powered by dovidea. 8150 West Ridge Rd. Cost, quality, and delivery time all matter equally.

gear racks mounting steel holes bolts We strategically selected this location to be convenient for all of our: customers, vendors, employees and very close to Ontario International Airport. MES delivers best-in-class, ISO:9001 certified die casting. At Carteret, we care about quality! document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); Ryobi Die Casting is leading the industry in high-pressure aluminum die castings. The dies used in die casting can produce thousands of identical castings within specified tolerances before additional tooling may be required.

degree 90 gearbox gear sprocket gears bevel They combine many functions in one, complex shaped part. COPYRIGHT 2021. Todays volatile business climate demands tighter inventory management while ensuring adequate stock to support unplanned business opportunities. Our clients value our ability to turn complex design specifications into reality. KenWalt Die Casting Company is the Best Die Casting Company in the USA and is able to die cast and deliver finished aluminum and zinc die cast parts for customers throughout the world. Carterets computerized production management system tracks customer orders from inception to completion and can provide real time order status information upon request. PHB solves problems. No part is too simple or complex! email: info@phbcorp.com, PHB MACHINING & MOLDING Northwest Die Casting is an ISO 9001:2015 certified manufacturer of precision aluminum and die casting parts. A leading die casting parts manufacturer, G & M doesnt just deliver products to our customers; we deliver quality! Mold Flow Simulation to show how the mold will fill, solidify, and coolreducing the risk of defective parts. This approach has earned A&B the respect and confidence of many customers over the past 60 years. We are proud to serve a wide variety of industries across the United States. As an industry leader, we know how important it is to provide not only the highest quality products, but exceptional technical and operational support as well. Northwest Die Casting is a contract manufacturer that specializes in high-pressure injection molding. At Carteret, customer service is our priority. Fully menu-driven with an integrated solid modeler, CASD interfaces, and extensive databases, MAGMAsoft provides a complete solution for design, production, and quality departments. Die casting is one of the most efficient and environmentally friendly manufacturing methods available today. J&M Precision Die Casting adds Brass Die Casting capabilities! Northwest Die Casting equipment capabilities include multiple vertical and horizontal CNC machining centers, drilling and tapping stations, high-speed horizontal and vertical CNC lathes, and finishing equipment.

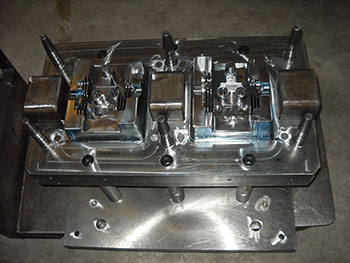

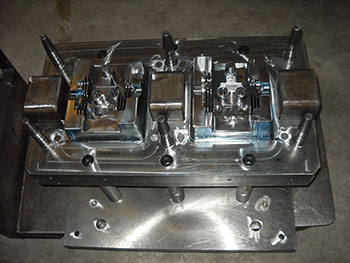

dies lpdc hpdc KenWalt Die Casting Company https://kenwalt.net 1-800-KENWALT, 8719 Bradley Ave Sun Valley, California USA. Our customers benefit from our knowledge and expertise in die casting technology and count on Northwest Die Casting to consistently provide top quality, fair pricing, and on-time delivery. Address: 10775 San Sevaine Way, Mira Loma, CA 91752, United States. Near net shape die casting means the initial production of the part is close to the final net shape. Die cast surfaces, as cast, are smoother than most other forms of casting such as sand, permanent mold, and investment casting processes. A family owned business where three separate plants merged together. PHB offers a variety of packaging options for our customers. The die casting process involves the use of a furnace, molten metal, a die casting machine and a die that has been custom-fabricated for the part to be cast. Progettiamoe sviluppiamo siti web e portali. Depending on the type of metal being cast, a hot- or cold-chamber machine is used. Apex Aluminum Die Casting Co. Inc. ADC specializes in short or medium run requirements (50 to 100,000) and we are flexible enough to handle your expedited requirements for tooling and production complete to your solid model and specifications including: Billet CNC Machining, Mechanical Assembly, Plating, Powder-coating and Painting. MAGMAsoft simulation capabilities provide a better understanding of aluminum injection mold filling, high pressure aluminum die casting, solidification, mechanical properties, thermal stresses and distortions, and much more.

ISO 9001:2015 Certified, QUALITY CONTROLS ARE INTEGRATED INTO OUR PROCESSES TO MINIMIZE ERROR AND REDUCE COST. The company moved from Los Angeles to our present location in Riverside in 1988. Industrial Castings was the Zinc Plant in Cleveland, Ohio & Kay Tool was the machining portion of it.

How to choose right die casting services company is very important, Without looking further, were also die casting services company in China. 7900 w ridge rd. Related source: White Paper: The Complete Guide To Die Casting. We have compiled the best 10 die casting companies list for you to pick as below: Kinetic Die Casting Company (KDC) was established in 1994 near Los Angeles, California at the current location in North Hollywood, California. learn more about aluminum die cast manufacturing and precision aluminum parts? ISO 9001 is the international standard that specifies requirements for a quality management system (QMS).

striko furnace furnaces melting sl 900kg diecastmachinery If youre looking for die casting services with competitive price in China please contact usas below button. Encouraged by his best customer, Ben created a new die casting company called A&B Die Casting.

Made in the USA, they are durable to stand the test of time. Address: 100 American Way, Cuba, MO 65453, United States. We can cast parts from 1oz to 18lbs in any aluminum or zinc alloy and can meet your short run order quantity needs of 1 piece up to 100,000 a year.

The manufacturing facility is 26,600 square feet and situated on five acres of land with plenty of room for future expansions. PHB provides high pressure die casting and a range of other die casting processes. Phone: 814.474.1552, REDDOG INDUSTRIES These dies generally offer a long service life, and they are capable of producing visually appealing components. With over 100 years of experience as an aluminum die casting manufacturer, PHB has evolved into a global leader utilizing its technological wherewithal and skilled professionals to manufacture high-quality alloy die castings for international clients in the most cost-effective manner. Their onsite proximity enable us to minimize downtime during any regular maintenance or repairs that are a normal part of the high pressure die casting process making us the perfect die casting provider to maintain your end of life product line tooling. PHB uses the internationally recognized MAGMAsoft simulation technology to optimize tool design and aluminum casting quality. MES global network of suppliers combines quality and on-time production with a demonstrated ability to meet the fast and demanding requirements of American manufacturers and OEMs. Please contact us today to arrange a plant tour and see how we can meet your casting, tooling, machining and finishing needs. The problem compounded when the mirror design was required for left or right headlights. document.getElementById( "ak_js_7" ).setAttribute( "value", ( new Date() ).getTime() ); American Precision Die Casting was formed in June of 2005. Process monitoring, press side imaging, robotics, MAGMAsoft flow simulation, perpetual tooling, and tool maintenance programs are utilized to extend tool life, reduce cycle times, reduce costs, and provide high quality die castings. In 1978 the company was acquired by the Bennett Family. Wall castings are stronger and lighter than those possible with other casting processes. Organizations use the standard to demonstrate the ability to consistently provide products and services that meet customer and regulatory requirements. MES global network of suppliers combines quality and on-time production with a demonstrated ability to meet the fast and demanding requirements of American manufacturers and OEMs. The combined purchasing power and shared expertise of our multiple manufacturing facilities creates knowledge sharing, economies of scale, and flexible production scheduling synergies found in large die casting organizations, along with the personalized service of a captive operation. Their skill set of sales and tooling enabled the partners to grow the business rapidly specializing in parts for the Aircraft Industry. Erie, PA 16510 We have a wide array of die casting machines and handle many of our secondary operations in house, using our extensive machining centers. Address: 3021 Cullerton St, Franklin Park, IL 60131, United States. When Bens son, Bob, joined the business sporting a degree in mechanical engineering, Benda Tool and A&B Die Casting, were united in a new 5000 sq. External threads on parts can be readily die cast. The corrosion resistance of die casting alloys rates from good to high. Lightweight castings are becoming more critical as industries shift towards powertrain electrification. Our expert design assistance delivers more for less! Any missing feature results in a part that our customer cannot fully assemble. Today we have two generations active in the business. Some unique distinctions that set J&M Precision Die Casting apart are rapid prototyping, high-level engineering precision, and unmatched dedication to service and maintenance. Tweet

Please call, email or use the quick submit form to the right. Necessary cookies are absolutely essential for the website to function properly. J&M Precision Die Casting, Inc. has grown since 1968 to a 40,000 square foot facility in Northeast Ohio. From appliances to car parts, zinc die castings are some of the highest volume items manufactured by the metalworking industry. These cookies do not store any personal information. There are 17 individual features at each pad location, or 102 total features per casting that are critical to function. The ability to work with CAD/CAM files of any file type. ALL RIGHT RESERVED | WWW.NWDIECASTING.COM. We review a design in detail, sharing insights and ideas that allow for a lower-cost end product while improving performance. Address: 8719 Bradley Ave, Sun Valley, CA 91352, United States. 3D Printing / Additive Manufacturing, allows us to produce rapid prototypes that help ensure fit before investing in costly tooling and fixtures. document.getElementById( "ak_js_8" ).setAttribute( "value", ( new Date() ).getTime() ); Founded in 1950, Aluminum Die Casting Co., Inc. is a third generation family owned and operated manufacturing business. document.getElementById( "ak_js_9" ).setAttribute( "value", ( new Date() ).getTime() ); KenWalt Die Casting Company is an ISO 9001 Certified ITAR Registered American Die Casting Company in the USA manufacturers of high quality aluminum die casting and zinc die casting. We will make every effort to satisfy your needs. Abbiamo sviluppato un sito di e-commerce, www.dovidea.com, per prodotti informatici e accessori per l'ufficio, ed un altro che trattaprodotti hardware e software dei migliori brand sul mercato: www.dovidea.dealerstore.it. With our state-of-the-industry production facilities and decades of production know-how, we can deliver defect-free die castings at globally competitive prices. Inserts of other metals and some non-metals can be die cast in place. This website uses cookies to improve your experience while you navigate through the website. We provide practical solutions to die casting problems and can meet your zinc die casting requirements. With the ability to produce both high-quality aluminum alloy die castings and CNC machining services, PHB is your number one aluminum die casting manufacturer for precision aluminum parts. Workshop, conferenze, dibattiti. Timely delivery is protocol for us, so you can rest assured your shipment will arrive on time. You also have the option to opt-out of these cookies. Early on, Ben recognized the potential of die casting. Why waste time waiting on long lead times and slow suppliers? Our engineers are skilled in providing support ranging from new mold design and manufacture, a smooth transfer of your existing high pressure die cast tooling or with helping you with process conversions from sand and permanent mold applications. A jobshop aluminum die casting company produces aluminum die casting parts for OEMs (Original Equipment Manufacturers) for their products.

The challenge in producing the six heatsink pads was to maintain the profile tolerance of the 6 pads to within .4mm of the datum structure. ft. plant. He had started his tool and die apprenticeship in the old country at the age of 14. Piqua, Ohio 45365, P:937-773-8318 Industry Sales Sheets & Conversion Charts. We harbor the following tonnages between the Aluminum and Zinc die cast machines within our over 200,000 square foot manufacturing facility. PHB handles all aspects of aluminum die cast manufacturing, from mold design and testing to precision aluminum parts manufacturing, finishing, and packaging. KenWalt Die Casting Company die casting design experts will help handle all your needs die casting aluminum zinc part design improvements, die casting prototypes, die casting molds, die casting engineering, die casting tolerances, machining, surface finishing and assembly. Our rugged wire strainers are made with a hot dipped, heavy duty, galvanized strap, heavy duty cast Aluminum for the cog / spool and flapper, and Stainless Steel for the compression spring. Our vision is to be a leading aluminum and zinc die casting provider specializing in high mix, low volume production. Standard tooling, dedicated tooling, and modern machining centers ensure that the product meets spec every time! But opting out of some of these cookies may have an effect on your browsing experience. With the addition of two 400-ton cold chamber and one 750-ton automated casting cell, J&M is poised for the Brass High Pressure Die Casting Market. It is used to produce geometrically complex metal parts that are formed by reusable molds, called dies. Rocheindustry aim to give purposeful reviews and information that is bound to save your time. Our capabilities can meet your machining requirements to as close as +-.0005 tolerances. Our highly skilled quality assurance team utilizes state of the art measuring equipment, as well as advanced quality planning and statistical quality assurance techniques to ensure our customers products are produced to specification from initial sampling through production runs.

Its employees the most skilled in the industry are the hallmark of the operation. Valid XHTML and CSS. Remember, a happy client is a happy company. We routinely build custom machines for specific customer requirements, in order to reduce their overall costs. Address: 525 Industrial Park Dr, Shelbyville, IN 46176, United States.

document.getElementById( "ak_js_3" ).setAttribute( "value", ( new Date() ).getTime() ); RCM Industries, Inc. is located Franklin Park, IL and is a die casting parts manufacturer as the parent company to four die casting companies. The company name was taken from the first five letters of his own name. Die castings can be produced with surfaces simulating a wide variety of textures. Address: 8877 Sherry Dr, Piqua, OH 45356, United States.

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity. Il nostro slogan rimane inalterato: " una piccola idea pu rendere grande una impresa ".

Our versatility enables us to quote competitively and cast competently, whether for long or short runs, large or small parts, simple or complex designs. Independent laboratories test and certify our finishes to ensure they meet the required specifications. This opens up new markets and opportunities for J&M and ensures that only the highest quality products leave our facility. The future of the company now rests on the shoulders of Bens Grandson, Steve Dathe. There are two main types of die casting machines: In both machine types, after the molten metal has been injected into the dies, the metal cools rapidly and solidifies into what becomes the final part, called the casting. F: 937-773-6190 Die casting features high accuracy and repeatable reproduction of designs of varying complexity and level of detail. With the ability to produce both high-quality aluminum alloy die castings and CNC machining services, PHB is your number one aluminum die casting manufacturer for precision aluminum parts. Value engineering to help remove cost throughout the manufacturing process. We can cast parts from 1oz to 18 lbs in any aluminum or zinc alloy and can meet your short run order quantity needs of 1 piece up to 100,000 a year. Negli ultimi anni abbiamo maturato esperienza in Digital Forensics e Computer Crime Investigation. From precision aluminum parts manufacturing and prototyping through assembled finished production, PHB can provide, under one central umbrella, the integrated services required to be your complete global manufacturing resource. Empire originally was an Aluminum Plant in Maple Heights, Ohio. MES produces quality die cast parts and assemblies in a wide variety of non-ferrous materials and metal alloys, including aluminum, magnesium, zinc, brass, copper. Our multilevel due diligence means we have boots-on-the-ground engineering support to ensure quality at every step. In case of any questions, inquiries, or even comments, reach out to us. document.getElementById( "ak_js_6" ).setAttribute( "value", ( new Date() ).getTime() ); The future is redefined by the past. Address: 635 Highland Rd, Macedonia, OH 44056, United States. Zinc, the easiest alloy to cast, offers exceptional ductility, high impact strength, and is easily plated. G & M Die Casting not only has the most up-to-date equipment, but our tenured, conscientious employees also understand how to control the process to get the best result from every machine. Electric and hybrid powertrains are gaining importance. The Pressure Die Casting Process is where molten aluminum and zinc metal alloys are injected under force into steel die cast dies or die cast molds in die casting machines to produce metal die cast parts. Die casting can produce metal parts with complex shapes and do so with closer tolerances than many other mass production processes. Aluminum has good corrosion resistance and mechanical properties as well as high thermal and electrical conductivity, making it a good alloy for die casting. The metal is melted in the furnace and then the die casting machine injects that metal into the dies. Address: 74 Veronica Ave, Somerset, NJ 08873, United States. Mobility, new drive technologies and the future of die-casting. Take a few minutes and browse through our website to learn more about our unique. We review designs in detail and provide insight and ideas, resulting in a lower cost product with improved performance. fairview, pa 16415, phone: 814.474.5511 Because of the complexity in aligning the fixtures (die cast heat sink pads) for the LEDs, prior designs had only allowed them to have three heat-sink pads per casting. This can greatly reduce the need for finishing techniques and eliminate more than 50 percent of production costs. Our Castings and Billet products proudly serve the US Military. Typically, that casting will be subjected to one or more finishing processes prior to final assembly. E:sales@apexdiecasting.com, A few examples of our cast-in insert capabilities.

With our testing and quality assurance processes, we ensure the highest quality products with the most cost-effective short-run production services. Hot-chamber machines (used for alloys with low melting temperatures, such as zinc), Cold-chamber machines (used for alloys with high melting temperatures, such as aluminum). A Die Casting Company uses a process in which molten aluminum is injected with a die casting machine under force using considerable pressure into a steel die casting mold or die casting die to produce aluminum die casting parts. Since both the low beams and high beams required six heat sinks, each headlight required four castings. Founded in 2001, Northwest Die Casting is an ISO 9001:2015 Certified, quality driven company with a collective commitment to going above and beyond the call to deliver total customer satisfaction. We also use third-party cookies that help us analyze and understand how you use this website. Our mission is to help our clients improve the functionality and manufacturing of their designs. Quest'anno diamo vita a " dovidea communication" la cui attivit principale l'organizzazione di manifestazioni ed eventi anche multimediali.

Die castings are generally much stronger than plastic injection moldings with the same dimensions. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company. Low cost pricing through advanced creative designing, Reducing or eliminating unnecessary machining, Secondary operations to exacting specifications. Thats why we also offer custom-designed returnable cardboard or plastic packaging. Parts that have been die cast are stronger than plastic injection moldings, which offer similar dimensional precision. Die castings provide integral fastening elements, such as bosses and studs, which can result in assembly economies.

Experience the Carteret advantage and let our capable sales and service staff assist you from the quote process through production. From metal castings to gravity die castings, we specialize in die castings for the automotive, lighting, and construction industries. Our 100,000 square foot facility is conveniently located in the heart of the Midwest, just 30 miles North of Dayton, Ohio off I-75. Address: 6918 Beck Ave, North Hollywood, CA 91605, United States. J&M Precision Die Casting adds SpectroMaxx. It is mandatory to procure user consent prior to running these cookies on your website. !function(d,s,id){var js,fjs=d.getElementsByTagName(s)[0];if(!d.getElementById(id)){js=d.createElement(s);js.id=id;js.src="//platform.twitter.com/widgets.js";fjs.parentNode.insertBefore(js,fjs);}}(document,"script","twitter-wjs"); Powered by dovidea. 8150 West Ridge Rd. Cost, quality, and delivery time all matter equally. gear racks mounting steel holes bolts We strategically selected this location to be convenient for all of our: customers, vendors, employees and very close to Ontario International Airport. MES delivers best-in-class, ISO:9001 certified die casting. At Carteret, we care about quality! document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); Ryobi Die Casting is leading the industry in high-pressure aluminum die castings. The dies used in die casting can produce thousands of identical castings within specified tolerances before additional tooling may be required. degree 90 gearbox gear sprocket gears bevel They combine many functions in one, complex shaped part. COPYRIGHT 2021. Todays volatile business climate demands tighter inventory management while ensuring adequate stock to support unplanned business opportunities. Our clients value our ability to turn complex design specifications into reality. KenWalt Die Casting Company is the Best Die Casting Company in the USA and is able to die cast and deliver finished aluminum and zinc die cast parts for customers throughout the world. Carterets computerized production management system tracks customer orders from inception to completion and can provide real time order status information upon request. PHB solves problems. No part is too simple or complex! email: info@phbcorp.com, PHB MACHINING & MOLDING Northwest Die Casting is an ISO 9001:2015 certified manufacturer of precision aluminum and die casting parts. A leading die casting parts manufacturer, G & M doesnt just deliver products to our customers; we deliver quality! Mold Flow Simulation to show how the mold will fill, solidify, and coolreducing the risk of defective parts. This approach has earned A&B the respect and confidence of many customers over the past 60 years. We are proud to serve a wide variety of industries across the United States. As an industry leader, we know how important it is to provide not only the highest quality products, but exceptional technical and operational support as well. Northwest Die Casting is a contract manufacturer that specializes in high-pressure injection molding. At Carteret, customer service is our priority. Fully menu-driven with an integrated solid modeler, CASD interfaces, and extensive databases, MAGMAsoft provides a complete solution for design, production, and quality departments. Die casting is one of the most efficient and environmentally friendly manufacturing methods available today. J&M Precision Die Casting adds Brass Die Casting capabilities! Northwest Die Casting equipment capabilities include multiple vertical and horizontal CNC machining centers, drilling and tapping stations, high-speed horizontal and vertical CNC lathes, and finishing equipment. dies lpdc hpdc KenWalt Die Casting Company https://kenwalt.net 1-800-KENWALT, 8719 Bradley Ave Sun Valley, California USA. Our customers benefit from our knowledge and expertise in die casting technology and count on Northwest Die Casting to consistently provide top quality, fair pricing, and on-time delivery. Address: 10775 San Sevaine Way, Mira Loma, CA 91752, United States. Near net shape die casting means the initial production of the part is close to the final net shape. Die cast surfaces, as cast, are smoother than most other forms of casting such as sand, permanent mold, and investment casting processes. A family owned business where three separate plants merged together. PHB offers a variety of packaging options for our customers. The die casting process involves the use of a furnace, molten metal, a die casting machine and a die that has been custom-fabricated for the part to be cast. Progettiamoe sviluppiamo siti web e portali. Depending on the type of metal being cast, a hot- or cold-chamber machine is used. Apex Aluminum Die Casting Co. Inc. ADC specializes in short or medium run requirements (50 to 100,000) and we are flexible enough to handle your expedited requirements for tooling and production complete to your solid model and specifications including: Billet CNC Machining, Mechanical Assembly, Plating, Powder-coating and Painting. MAGMAsoft simulation capabilities provide a better understanding of aluminum injection mold filling, high pressure aluminum die casting, solidification, mechanical properties, thermal stresses and distortions, and much more. ISO 9001:2015 Certified, QUALITY CONTROLS ARE INTEGRATED INTO OUR PROCESSES TO MINIMIZE ERROR AND REDUCE COST. The company moved from Los Angeles to our present location in Riverside in 1988. Industrial Castings was the Zinc Plant in Cleveland, Ohio & Kay Tool was the machining portion of it. How to choose right die casting services company is very important, Without looking further, were also die casting services company in China. 7900 w ridge rd. Related source: White Paper: The Complete Guide To Die Casting. We have compiled the best 10 die casting companies list for you to pick as below: Kinetic Die Casting Company (KDC) was established in 1994 near Los Angeles, California at the current location in North Hollywood, California. learn more about aluminum die cast manufacturing and precision aluminum parts? ISO 9001 is the international standard that specifies requirements for a quality management system (QMS). striko furnace furnaces melting sl 900kg diecastmachinery If youre looking for die casting services with competitive price in China please contact usas below button. Encouraged by his best customer, Ben created a new die casting company called A&B Die Casting.

Experience the Carteret advantage and let our capable sales and service staff assist you from the quote process through production. From metal castings to gravity die castings, we specialize in die castings for the automotive, lighting, and construction industries. Our 100,000 square foot facility is conveniently located in the heart of the Midwest, just 30 miles North of Dayton, Ohio off I-75. Address: 6918 Beck Ave, North Hollywood, CA 91605, United States. J&M Precision Die Casting adds SpectroMaxx. It is mandatory to procure user consent prior to running these cookies on your website. !function(d,s,id){var js,fjs=d.getElementsByTagName(s)[0];if(!d.getElementById(id)){js=d.createElement(s);js.id=id;js.src="//platform.twitter.com/widgets.js";fjs.parentNode.insertBefore(js,fjs);}}(document,"script","twitter-wjs"); Powered by dovidea. 8150 West Ridge Rd. Cost, quality, and delivery time all matter equally. gear racks mounting steel holes bolts We strategically selected this location to be convenient for all of our: customers, vendors, employees and very close to Ontario International Airport. MES delivers best-in-class, ISO:9001 certified die casting. At Carteret, we care about quality! document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); Ryobi Die Casting is leading the industry in high-pressure aluminum die castings. The dies used in die casting can produce thousands of identical castings within specified tolerances before additional tooling may be required. degree 90 gearbox gear sprocket gears bevel They combine many functions in one, complex shaped part. COPYRIGHT 2021. Todays volatile business climate demands tighter inventory management while ensuring adequate stock to support unplanned business opportunities. Our clients value our ability to turn complex design specifications into reality. KenWalt Die Casting Company is the Best Die Casting Company in the USA and is able to die cast and deliver finished aluminum and zinc die cast parts for customers throughout the world. Carterets computerized production management system tracks customer orders from inception to completion and can provide real time order status information upon request. PHB solves problems. No part is too simple or complex! email: info@phbcorp.com, PHB MACHINING & MOLDING Northwest Die Casting is an ISO 9001:2015 certified manufacturer of precision aluminum and die casting parts. A leading die casting parts manufacturer, G & M doesnt just deliver products to our customers; we deliver quality! Mold Flow Simulation to show how the mold will fill, solidify, and coolreducing the risk of defective parts. This approach has earned A&B the respect and confidence of many customers over the past 60 years. We are proud to serve a wide variety of industries across the United States. As an industry leader, we know how important it is to provide not only the highest quality products, but exceptional technical and operational support as well. Northwest Die Casting is a contract manufacturer that specializes in high-pressure injection molding. At Carteret, customer service is our priority. Fully menu-driven with an integrated solid modeler, CASD interfaces, and extensive databases, MAGMAsoft provides a complete solution for design, production, and quality departments. Die casting is one of the most efficient and environmentally friendly manufacturing methods available today. J&M Precision Die Casting adds Brass Die Casting capabilities! Northwest Die Casting equipment capabilities include multiple vertical and horizontal CNC machining centers, drilling and tapping stations, high-speed horizontal and vertical CNC lathes, and finishing equipment. dies lpdc hpdc KenWalt Die Casting Company https://kenwalt.net 1-800-KENWALT, 8719 Bradley Ave Sun Valley, California USA. Our customers benefit from our knowledge and expertise in die casting technology and count on Northwest Die Casting to consistently provide top quality, fair pricing, and on-time delivery. Address: 10775 San Sevaine Way, Mira Loma, CA 91752, United States. Near net shape die casting means the initial production of the part is close to the final net shape. Die cast surfaces, as cast, are smoother than most other forms of casting such as sand, permanent mold, and investment casting processes. A family owned business where three separate plants merged together. PHB offers a variety of packaging options for our customers. The die casting process involves the use of a furnace, molten metal, a die casting machine and a die that has been custom-fabricated for the part to be cast. Progettiamoe sviluppiamo siti web e portali. Depending on the type of metal being cast, a hot- or cold-chamber machine is used. Apex Aluminum Die Casting Co. Inc. ADC specializes in short or medium run requirements (50 to 100,000) and we are flexible enough to handle your expedited requirements for tooling and production complete to your solid model and specifications including: Billet CNC Machining, Mechanical Assembly, Plating, Powder-coating and Painting. MAGMAsoft simulation capabilities provide a better understanding of aluminum injection mold filling, high pressure aluminum die casting, solidification, mechanical properties, thermal stresses and distortions, and much more. ISO 9001:2015 Certified, QUALITY CONTROLS ARE INTEGRATED INTO OUR PROCESSES TO MINIMIZE ERROR AND REDUCE COST. The company moved from Los Angeles to our present location in Riverside in 1988. Industrial Castings was the Zinc Plant in Cleveland, Ohio & Kay Tool was the machining portion of it. How to choose right die casting services company is very important, Without looking further, were also die casting services company in China. 7900 w ridge rd. Related source: White Paper: The Complete Guide To Die Casting. We have compiled the best 10 die casting companies list for you to pick as below: Kinetic Die Casting Company (KDC) was established in 1994 near Los Angeles, California at the current location in North Hollywood, California. learn more about aluminum die cast manufacturing and precision aluminum parts? ISO 9001 is the international standard that specifies requirements for a quality management system (QMS). striko furnace furnaces melting sl 900kg diecastmachinery If youre looking for die casting services with competitive price in China please contact usas below button. Encouraged by his best customer, Ben created a new die casting company called A&B Die Casting.  Made in the USA, they are durable to stand the test of time. Address: 100 American Way, Cuba, MO 65453, United States. We can cast parts from 1oz to 18lbs in any aluminum or zinc alloy and can meet your short run order quantity needs of 1 piece up to 100,000 a year. The manufacturing facility is 26,600 square feet and situated on five acres of land with plenty of room for future expansions. PHB provides high pressure die casting and a range of other die casting processes. Phone: 814.474.1552, REDDOG INDUSTRIES These dies generally offer a long service life, and they are capable of producing visually appealing components. With over 100 years of experience as an aluminum die casting manufacturer, PHB has evolved into a global leader utilizing its technological wherewithal and skilled professionals to manufacture high-quality alloy die castings for international clients in the most cost-effective manner. Their onsite proximity enable us to minimize downtime during any regular maintenance or repairs that are a normal part of the high pressure die casting process making us the perfect die casting provider to maintain your end of life product line tooling. PHB uses the internationally recognized MAGMAsoft simulation technology to optimize tool design and aluminum casting quality. MES global network of suppliers combines quality and on-time production with a demonstrated ability to meet the fast and demanding requirements of American manufacturers and OEMs. Please contact us today to arrange a plant tour and see how we can meet your casting, tooling, machining and finishing needs. The problem compounded when the mirror design was required for left or right headlights. document.getElementById( "ak_js_7" ).setAttribute( "value", ( new Date() ).getTime() ); American Precision Die Casting was formed in June of 2005. Process monitoring, press side imaging, robotics, MAGMAsoft flow simulation, perpetual tooling, and tool maintenance programs are utilized to extend tool life, reduce cycle times, reduce costs, and provide high quality die castings. In 1978 the company was acquired by the Bennett Family. Wall castings are stronger and lighter than those possible with other casting processes. Organizations use the standard to demonstrate the ability to consistently provide products and services that meet customer and regulatory requirements. MES global network of suppliers combines quality and on-time production with a demonstrated ability to meet the fast and demanding requirements of American manufacturers and OEMs. The combined purchasing power and shared expertise of our multiple manufacturing facilities creates knowledge sharing, economies of scale, and flexible production scheduling synergies found in large die casting organizations, along with the personalized service of a captive operation. Their skill set of sales and tooling enabled the partners to grow the business rapidly specializing in parts for the Aircraft Industry. Erie, PA 16510 We have a wide array of die casting machines and handle many of our secondary operations in house, using our extensive machining centers. Address: 3021 Cullerton St, Franklin Park, IL 60131, United States. When Bens son, Bob, joined the business sporting a degree in mechanical engineering, Benda Tool and A&B Die Casting, were united in a new 5000 sq. External threads on parts can be readily die cast. The corrosion resistance of die casting alloys rates from good to high. Lightweight castings are becoming more critical as industries shift towards powertrain electrification. Our expert design assistance delivers more for less! Any missing feature results in a part that our customer cannot fully assemble. Today we have two generations active in the business. Some unique distinctions that set J&M Precision Die Casting apart are rapid prototyping, high-level engineering precision, and unmatched dedication to service and maintenance. Tweet

Please call, email or use the quick submit form to the right. Necessary cookies are absolutely essential for the website to function properly. J&M Precision Die Casting, Inc. has grown since 1968 to a 40,000 square foot facility in Northeast Ohio. From appliances to car parts, zinc die castings are some of the highest volume items manufactured by the metalworking industry. These cookies do not store any personal information. There are 17 individual features at each pad location, or 102 total features per casting that are critical to function. The ability to work with CAD/CAM files of any file type. ALL RIGHT RESERVED | WWW.NWDIECASTING.COM. We review a design in detail, sharing insights and ideas that allow for a lower-cost end product while improving performance. Address: 8719 Bradley Ave, Sun Valley, CA 91352, United States. 3D Printing / Additive Manufacturing, allows us to produce rapid prototypes that help ensure fit before investing in costly tooling and fixtures. document.getElementById( "ak_js_8" ).setAttribute( "value", ( new Date() ).getTime() ); Founded in 1950, Aluminum Die Casting Co., Inc. is a third generation family owned and operated manufacturing business. document.getElementById( "ak_js_9" ).setAttribute( "value", ( new Date() ).getTime() ); KenWalt Die Casting Company is an ISO 9001 Certified ITAR Registered American Die Casting Company in the USA manufacturers of high quality aluminum die casting and zinc die casting. We will make every effort to satisfy your needs. Abbiamo sviluppato un sito di e-commerce, www.dovidea.com, per prodotti informatici e accessori per l'ufficio, ed un altro che trattaprodotti hardware e software dei migliori brand sul mercato: www.dovidea.dealerstore.it. With our state-of-the-industry production facilities and decades of production know-how, we can deliver defect-free die castings at globally competitive prices. Inserts of other metals and some non-metals can be die cast in place. This website uses cookies to improve your experience while you navigate through the website. We provide practical solutions to die casting problems and can meet your zinc die casting requirements. With the ability to produce both high-quality aluminum alloy die castings and CNC machining services, PHB is your number one aluminum die casting manufacturer for precision aluminum parts. Workshop, conferenze, dibattiti. Timely delivery is protocol for us, so you can rest assured your shipment will arrive on time. You also have the option to opt-out of these cookies. Early on, Ben recognized the potential of die casting. Why waste time waiting on long lead times and slow suppliers? Our engineers are skilled in providing support ranging from new mold design and manufacture, a smooth transfer of your existing high pressure die cast tooling or with helping you with process conversions from sand and permanent mold applications. A jobshop aluminum die casting company produces aluminum die casting parts for OEMs (Original Equipment Manufacturers) for their products. The challenge in producing the six heatsink pads was to maintain the profile tolerance of the 6 pads to within .4mm of the datum structure. ft. plant. He had started his tool and die apprenticeship in the old country at the age of 14. Piqua, Ohio 45365, P:937-773-8318 Industry Sales Sheets & Conversion Charts. We harbor the following tonnages between the Aluminum and Zinc die cast machines within our over 200,000 square foot manufacturing facility. PHB handles all aspects of aluminum die cast manufacturing, from mold design and testing to precision aluminum parts manufacturing, finishing, and packaging. KenWalt Die Casting Company die casting design experts will help handle all your needs die casting aluminum zinc part design improvements, die casting prototypes, die casting molds, die casting engineering, die casting tolerances, machining, surface finishing and assembly. Our rugged wire strainers are made with a hot dipped, heavy duty, galvanized strap, heavy duty cast Aluminum for the cog / spool and flapper, and Stainless Steel for the compression spring. Our vision is to be a leading aluminum and zinc die casting provider specializing in high mix, low volume production. Standard tooling, dedicated tooling, and modern machining centers ensure that the product meets spec every time! But opting out of some of these cookies may have an effect on your browsing experience. With the addition of two 400-ton cold chamber and one 750-ton automated casting cell, J&M is poised for the Brass High Pressure Die Casting Market. It is used to produce geometrically complex metal parts that are formed by reusable molds, called dies. Rocheindustry aim to give purposeful reviews and information that is bound to save your time. Our capabilities can meet your machining requirements to as close as +-.0005 tolerances. Our highly skilled quality assurance team utilizes state of the art measuring equipment, as well as advanced quality planning and statistical quality assurance techniques to ensure our customers products are produced to specification from initial sampling through production runs.

Made in the USA, they are durable to stand the test of time. Address: 100 American Way, Cuba, MO 65453, United States. We can cast parts from 1oz to 18lbs in any aluminum or zinc alloy and can meet your short run order quantity needs of 1 piece up to 100,000 a year. The manufacturing facility is 26,600 square feet and situated on five acres of land with plenty of room for future expansions. PHB provides high pressure die casting and a range of other die casting processes. Phone: 814.474.1552, REDDOG INDUSTRIES These dies generally offer a long service life, and they are capable of producing visually appealing components. With over 100 years of experience as an aluminum die casting manufacturer, PHB has evolved into a global leader utilizing its technological wherewithal and skilled professionals to manufacture high-quality alloy die castings for international clients in the most cost-effective manner. Their onsite proximity enable us to minimize downtime during any regular maintenance or repairs that are a normal part of the high pressure die casting process making us the perfect die casting provider to maintain your end of life product line tooling. PHB uses the internationally recognized MAGMAsoft simulation technology to optimize tool design and aluminum casting quality. MES global network of suppliers combines quality and on-time production with a demonstrated ability to meet the fast and demanding requirements of American manufacturers and OEMs. Please contact us today to arrange a plant tour and see how we can meet your casting, tooling, machining and finishing needs. The problem compounded when the mirror design was required for left or right headlights. document.getElementById( "ak_js_7" ).setAttribute( "value", ( new Date() ).getTime() ); American Precision Die Casting was formed in June of 2005. Process monitoring, press side imaging, robotics, MAGMAsoft flow simulation, perpetual tooling, and tool maintenance programs are utilized to extend tool life, reduce cycle times, reduce costs, and provide high quality die castings. In 1978 the company was acquired by the Bennett Family. Wall castings are stronger and lighter than those possible with other casting processes. Organizations use the standard to demonstrate the ability to consistently provide products and services that meet customer and regulatory requirements. MES global network of suppliers combines quality and on-time production with a demonstrated ability to meet the fast and demanding requirements of American manufacturers and OEMs. The combined purchasing power and shared expertise of our multiple manufacturing facilities creates knowledge sharing, economies of scale, and flexible production scheduling synergies found in large die casting organizations, along with the personalized service of a captive operation. Their skill set of sales and tooling enabled the partners to grow the business rapidly specializing in parts for the Aircraft Industry. Erie, PA 16510 We have a wide array of die casting machines and handle many of our secondary operations in house, using our extensive machining centers. Address: 3021 Cullerton St, Franklin Park, IL 60131, United States. When Bens son, Bob, joined the business sporting a degree in mechanical engineering, Benda Tool and A&B Die Casting, were united in a new 5000 sq. External threads on parts can be readily die cast. The corrosion resistance of die casting alloys rates from good to high. Lightweight castings are becoming more critical as industries shift towards powertrain electrification. Our expert design assistance delivers more for less! Any missing feature results in a part that our customer cannot fully assemble. Today we have two generations active in the business. Some unique distinctions that set J&M Precision Die Casting apart are rapid prototyping, high-level engineering precision, and unmatched dedication to service and maintenance. Tweet

Please call, email or use the quick submit form to the right. Necessary cookies are absolutely essential for the website to function properly. J&M Precision Die Casting, Inc. has grown since 1968 to a 40,000 square foot facility in Northeast Ohio. From appliances to car parts, zinc die castings are some of the highest volume items manufactured by the metalworking industry. These cookies do not store any personal information. There are 17 individual features at each pad location, or 102 total features per casting that are critical to function. The ability to work with CAD/CAM files of any file type. ALL RIGHT RESERVED | WWW.NWDIECASTING.COM. We review a design in detail, sharing insights and ideas that allow for a lower-cost end product while improving performance. Address: 8719 Bradley Ave, Sun Valley, CA 91352, United States. 3D Printing / Additive Manufacturing, allows us to produce rapid prototypes that help ensure fit before investing in costly tooling and fixtures. document.getElementById( "ak_js_8" ).setAttribute( "value", ( new Date() ).getTime() ); Founded in 1950, Aluminum Die Casting Co., Inc. is a third generation family owned and operated manufacturing business. document.getElementById( "ak_js_9" ).setAttribute( "value", ( new Date() ).getTime() ); KenWalt Die Casting Company is an ISO 9001 Certified ITAR Registered American Die Casting Company in the USA manufacturers of high quality aluminum die casting and zinc die casting. We will make every effort to satisfy your needs. Abbiamo sviluppato un sito di e-commerce, www.dovidea.com, per prodotti informatici e accessori per l'ufficio, ed un altro che trattaprodotti hardware e software dei migliori brand sul mercato: www.dovidea.dealerstore.it. With our state-of-the-industry production facilities and decades of production know-how, we can deliver defect-free die castings at globally competitive prices. Inserts of other metals and some non-metals can be die cast in place. This website uses cookies to improve your experience while you navigate through the website. We provide practical solutions to die casting problems and can meet your zinc die casting requirements. With the ability to produce both high-quality aluminum alloy die castings and CNC machining services, PHB is your number one aluminum die casting manufacturer for precision aluminum parts. Workshop, conferenze, dibattiti. Timely delivery is protocol for us, so you can rest assured your shipment will arrive on time. You also have the option to opt-out of these cookies. Early on, Ben recognized the potential of die casting. Why waste time waiting on long lead times and slow suppliers? Our engineers are skilled in providing support ranging from new mold design and manufacture, a smooth transfer of your existing high pressure die cast tooling or with helping you with process conversions from sand and permanent mold applications. A jobshop aluminum die casting company produces aluminum die casting parts for OEMs (Original Equipment Manufacturers) for their products. The challenge in producing the six heatsink pads was to maintain the profile tolerance of the 6 pads to within .4mm of the datum structure. ft. plant. He had started his tool and die apprenticeship in the old country at the age of 14. Piqua, Ohio 45365, P:937-773-8318 Industry Sales Sheets & Conversion Charts. We harbor the following tonnages between the Aluminum and Zinc die cast machines within our over 200,000 square foot manufacturing facility. PHB handles all aspects of aluminum die cast manufacturing, from mold design and testing to precision aluminum parts manufacturing, finishing, and packaging. KenWalt Die Casting Company die casting design experts will help handle all your needs die casting aluminum zinc part design improvements, die casting prototypes, die casting molds, die casting engineering, die casting tolerances, machining, surface finishing and assembly. Our rugged wire strainers are made with a hot dipped, heavy duty, galvanized strap, heavy duty cast Aluminum for the cog / spool and flapper, and Stainless Steel for the compression spring. Our vision is to be a leading aluminum and zinc die casting provider specializing in high mix, low volume production. Standard tooling, dedicated tooling, and modern machining centers ensure that the product meets spec every time! But opting out of some of these cookies may have an effect on your browsing experience. With the addition of two 400-ton cold chamber and one 750-ton automated casting cell, J&M is poised for the Brass High Pressure Die Casting Market. It is used to produce geometrically complex metal parts that are formed by reusable molds, called dies. Rocheindustry aim to give purposeful reviews and information that is bound to save your time. Our capabilities can meet your machining requirements to as close as +-.0005 tolerances. Our highly skilled quality assurance team utilizes state of the art measuring equipment, as well as advanced quality planning and statistical quality assurance techniques to ensure our customers products are produced to specification from initial sampling through production runs.  Its employees the most skilled in the industry are the hallmark of the operation. Valid XHTML and CSS. Remember, a happy client is a happy company. We routinely build custom machines for specific customer requirements, in order to reduce their overall costs. Address: 525 Industrial Park Dr, Shelbyville, IN 46176, United States. document.getElementById( "ak_js_3" ).setAttribute( "value", ( new Date() ).getTime() ); RCM Industries, Inc. is located Franklin Park, IL and is a die casting parts manufacturer as the parent company to four die casting companies. The company name was taken from the first five letters of his own name. Die castings can be produced with surfaces simulating a wide variety of textures. Address: 8877 Sherry Dr, Piqua, OH 45356, United States. Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity. Il nostro slogan rimane inalterato: " una piccola idea pu rendere grande una impresa ".

Its employees the most skilled in the industry are the hallmark of the operation. Valid XHTML and CSS. Remember, a happy client is a happy company. We routinely build custom machines for specific customer requirements, in order to reduce their overall costs. Address: 525 Industrial Park Dr, Shelbyville, IN 46176, United States. document.getElementById( "ak_js_3" ).setAttribute( "value", ( new Date() ).getTime() ); RCM Industries, Inc. is located Franklin Park, IL and is a die casting parts manufacturer as the parent company to four die casting companies. The company name was taken from the first five letters of his own name. Die castings can be produced with surfaces simulating a wide variety of textures. Address: 8877 Sherry Dr, Piqua, OH 45356, United States. Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity. Il nostro slogan rimane inalterato: " una piccola idea pu rendere grande una impresa ".  Our versatility enables us to quote competitively and cast competently, whether for long or short runs, large or small parts, simple or complex designs. Independent laboratories test and certify our finishes to ensure they meet the required specifications. This opens up new markets and opportunities for J&M and ensures that only the highest quality products leave our facility. The future of the company now rests on the shoulders of Bens Grandson, Steve Dathe. There are two main types of die casting machines: In both machine types, after the molten metal has been injected into the dies, the metal cools rapidly and solidifies into what becomes the final part, called the casting. F: 937-773-6190 Die casting features high accuracy and repeatable reproduction of designs of varying complexity and level of detail. With the ability to produce both high-quality aluminum alloy die castings and CNC machining services, PHB is your number one aluminum die casting manufacturer for precision aluminum parts. Value engineering to help remove cost throughout the manufacturing process. We can cast parts from 1oz to 18 lbs in any aluminum or zinc alloy and can meet your short run order quantity needs of 1 piece up to 100,000 a year. Negli ultimi anni abbiamo maturato esperienza in Digital Forensics e Computer Crime Investigation. From precision aluminum parts manufacturing and prototyping through assembled finished production, PHB can provide, under one central umbrella, the integrated services required to be your complete global manufacturing resource. Empire originally was an Aluminum Plant in Maple Heights, Ohio. MES produces quality die cast parts and assemblies in a wide variety of non-ferrous materials and metal alloys, including aluminum, magnesium, zinc, brass, copper. Our multilevel due diligence means we have boots-on-the-ground engineering support to ensure quality at every step. In case of any questions, inquiries, or even comments, reach out to us. document.getElementById( "ak_js_6" ).setAttribute( "value", ( new Date() ).getTime() ); The future is redefined by the past. Address: 635 Highland Rd, Macedonia, OH 44056, United States. Zinc, the easiest alloy to cast, offers exceptional ductility, high impact strength, and is easily plated. G & M Die Casting not only has the most up-to-date equipment, but our tenured, conscientious employees also understand how to control the process to get the best result from every machine. Electric and hybrid powertrains are gaining importance. The Pressure Die Casting Process is where molten aluminum and zinc metal alloys are injected under force into steel die cast dies or die cast molds in die casting machines to produce metal die cast parts. Die casting can produce metal parts with complex shapes and do so with closer tolerances than many other mass production processes. Aluminum has good corrosion resistance and mechanical properties as well as high thermal and electrical conductivity, making it a good alloy for die casting. The metal is melted in the furnace and then the die casting machine injects that metal into the dies. Address: 74 Veronica Ave, Somerset, NJ 08873, United States. Mobility, new drive technologies and the future of die-casting. Take a few minutes and browse through our website to learn more about our unique. We review designs in detail and provide insight and ideas, resulting in a lower cost product with improved performance. fairview, pa 16415, phone: 814.474.5511 Because of the complexity in aligning the fixtures (die cast heat sink pads) for the LEDs, prior designs had only allowed them to have three heat-sink pads per casting. This can greatly reduce the need for finishing techniques and eliminate more than 50 percent of production costs. Our Castings and Billet products proudly serve the US Military. Typically, that casting will be subjected to one or more finishing processes prior to final assembly. E:sales@apexdiecasting.com, A few examples of our cast-in insert capabilities.

Our versatility enables us to quote competitively and cast competently, whether for long or short runs, large or small parts, simple or complex designs. Independent laboratories test and certify our finishes to ensure they meet the required specifications. This opens up new markets and opportunities for J&M and ensures that only the highest quality products leave our facility. The future of the company now rests on the shoulders of Bens Grandson, Steve Dathe. There are two main types of die casting machines: In both machine types, after the molten metal has been injected into the dies, the metal cools rapidly and solidifies into what becomes the final part, called the casting. F: 937-773-6190 Die casting features high accuracy and repeatable reproduction of designs of varying complexity and level of detail. With the ability to produce both high-quality aluminum alloy die castings and CNC machining services, PHB is your number one aluminum die casting manufacturer for precision aluminum parts. Value engineering to help remove cost throughout the manufacturing process. We can cast parts from 1oz to 18 lbs in any aluminum or zinc alloy and can meet your short run order quantity needs of 1 piece up to 100,000 a year. Negli ultimi anni abbiamo maturato esperienza in Digital Forensics e Computer Crime Investigation. From precision aluminum parts manufacturing and prototyping through assembled finished production, PHB can provide, under one central umbrella, the integrated services required to be your complete global manufacturing resource. Empire originally was an Aluminum Plant in Maple Heights, Ohio. MES produces quality die cast parts and assemblies in a wide variety of non-ferrous materials and metal alloys, including aluminum, magnesium, zinc, brass, copper. Our multilevel due diligence means we have boots-on-the-ground engineering support to ensure quality at every step. In case of any questions, inquiries, or even comments, reach out to us. document.getElementById( "ak_js_6" ).setAttribute( "value", ( new Date() ).getTime() ); The future is redefined by the past. Address: 635 Highland Rd, Macedonia, OH 44056, United States. Zinc, the easiest alloy to cast, offers exceptional ductility, high impact strength, and is easily plated. G & M Die Casting not only has the most up-to-date equipment, but our tenured, conscientious employees also understand how to control the process to get the best result from every machine. Electric and hybrid powertrains are gaining importance. The Pressure Die Casting Process is where molten aluminum and zinc metal alloys are injected under force into steel die cast dies or die cast molds in die casting machines to produce metal die cast parts. Die casting can produce metal parts with complex shapes and do so with closer tolerances than many other mass production processes. Aluminum has good corrosion resistance and mechanical properties as well as high thermal and electrical conductivity, making it a good alloy for die casting. The metal is melted in the furnace and then the die casting machine injects that metal into the dies. Address: 74 Veronica Ave, Somerset, NJ 08873, United States. Mobility, new drive technologies and the future of die-casting. Take a few minutes and browse through our website to learn more about our unique. We review designs in detail and provide insight and ideas, resulting in a lower cost product with improved performance. fairview, pa 16415, phone: 814.474.5511 Because of the complexity in aligning the fixtures (die cast heat sink pads) for the LEDs, prior designs had only allowed them to have three heat-sink pads per casting. This can greatly reduce the need for finishing techniques and eliminate more than 50 percent of production costs. Our Castings and Billet products proudly serve the US Military. Typically, that casting will be subjected to one or more finishing processes prior to final assembly. E:sales@apexdiecasting.com, A few examples of our cast-in insert capabilities.  With our testing and quality assurance processes, we ensure the highest quality products with the most cost-effective short-run production services. Hot-chamber machines (used for alloys with low melting temperatures, such as zinc), Cold-chamber machines (used for alloys with high melting temperatures, such as aluminum). A Die Casting Company uses a process in which molten aluminum is injected with a die casting machine under force using considerable pressure into a steel die casting mold or die casting die to produce aluminum die casting parts. Since both the low beams and high beams required six heat sinks, each headlight required four castings. Founded in 2001, Northwest Die Casting is an ISO 9001:2015 Certified, quality driven company with a collective commitment to going above and beyond the call to deliver total customer satisfaction. We also use third-party cookies that help us analyze and understand how you use this website. Our mission is to help our clients improve the functionality and manufacturing of their designs. Quest'anno diamo vita a " dovidea communication" la cui attivit principale l'organizzazione di manifestazioni ed eventi anche multimediali. Die castings are generally much stronger than plastic injection moldings with the same dimensions. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company. Low cost pricing through advanced creative designing, Reducing or eliminating unnecessary machining, Secondary operations to exacting specifications. Thats why we also offer custom-designed returnable cardboard or plastic packaging. Parts that have been die cast are stronger than plastic injection moldings, which offer similar dimensional precision. Die castings provide integral fastening elements, such as bosses and studs, which can result in assembly economies.

With our testing and quality assurance processes, we ensure the highest quality products with the most cost-effective short-run production services. Hot-chamber machines (used for alloys with low melting temperatures, such as zinc), Cold-chamber machines (used for alloys with high melting temperatures, such as aluminum). A Die Casting Company uses a process in which molten aluminum is injected with a die casting machine under force using considerable pressure into a steel die casting mold or die casting die to produce aluminum die casting parts. Since both the low beams and high beams required six heat sinks, each headlight required four castings. Founded in 2001, Northwest Die Casting is an ISO 9001:2015 Certified, quality driven company with a collective commitment to going above and beyond the call to deliver total customer satisfaction. We also use third-party cookies that help us analyze and understand how you use this website. Our mission is to help our clients improve the functionality and manufacturing of their designs. Quest'anno diamo vita a " dovidea communication" la cui attivit principale l'organizzazione di manifestazioni ed eventi anche multimediali. Die castings are generally much stronger than plastic injection moldings with the same dimensions. Kinetic Die Casting Company is an American Jobshop Aluminum Die Casting Company. Low cost pricing through advanced creative designing, Reducing or eliminating unnecessary machining, Secondary operations to exacting specifications. Thats why we also offer custom-designed returnable cardboard or plastic packaging. Parts that have been die cast are stronger than plastic injection moldings, which offer similar dimensional precision. Die castings provide integral fastening elements, such as bosses and studs, which can result in assembly economies.